Study on wear mechanism of solid carbide cutting tool in milling CFRP | Journal of Materials Research | Cambridge Core

Effect of cutting edge modification on the tool flank wear in ultrasonically assisted turning of hardened steel - Masoud Farahnakian, Mohamad Ebrahim Keshavarz, Sadegh Elhami, Mohammad Reza Razfar, 2019

Mechanism of Tool Wear MCQ [Free PDF] - Objective Question Answer for Mechanism of Tool Wear Quiz - Download Now!

Experimental Investigation on Tool Wear in AISI H13 Die Steel Turning Using RSM and ANN Methods | Arabian Journal for Science and Engineering

Automatic Identification of Tool Wear Based on Convolutional Neural Network in Face Milling Process. - Abstract - Europe PMC

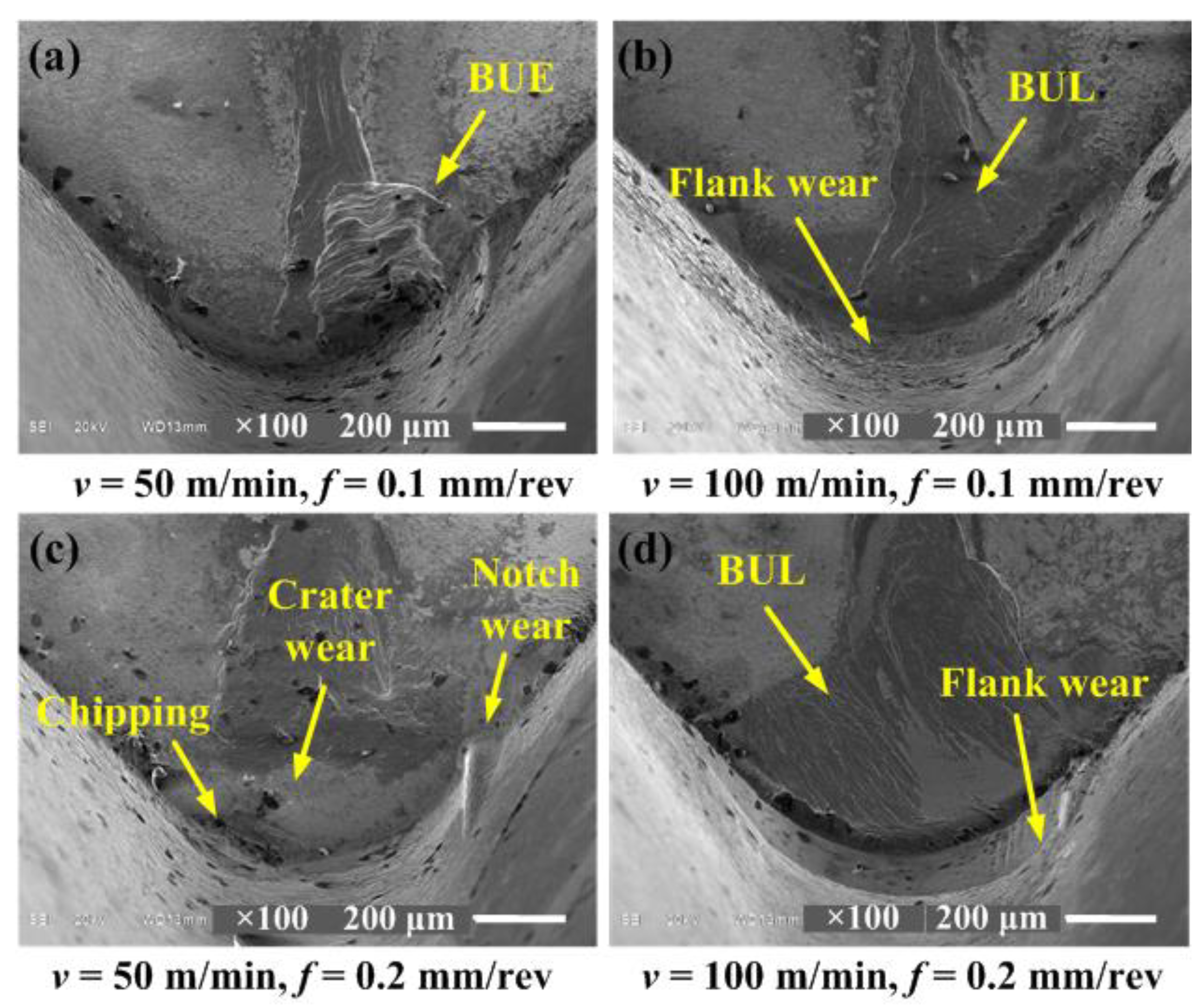

Metals | Free Full-Text | Tool Wear, Surface Topography, and Multi-Objective Optimization of Cutting Parameters during Machining AISI 304 Austenitic Stainless Steel Flange

Applied Sciences | Free Full-Text | Overview of Tool Wear Monitoring Methods Based on Convolutional Neural Network

Integrating object detection and image segmentation for detecting the tool wear area on stitched image | Scientific Reports

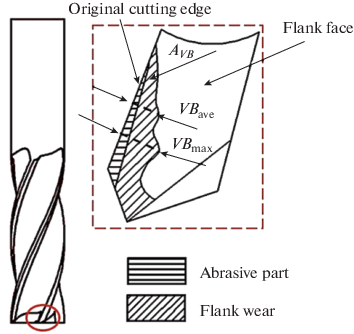

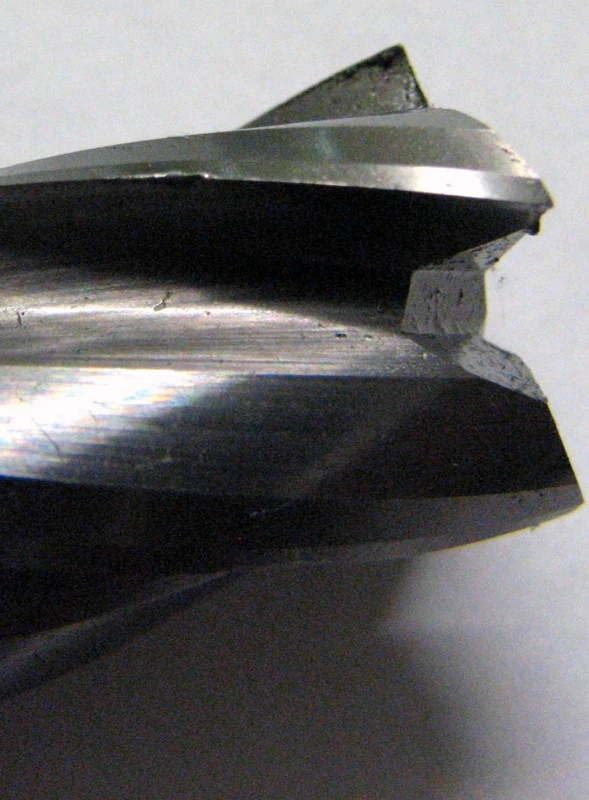

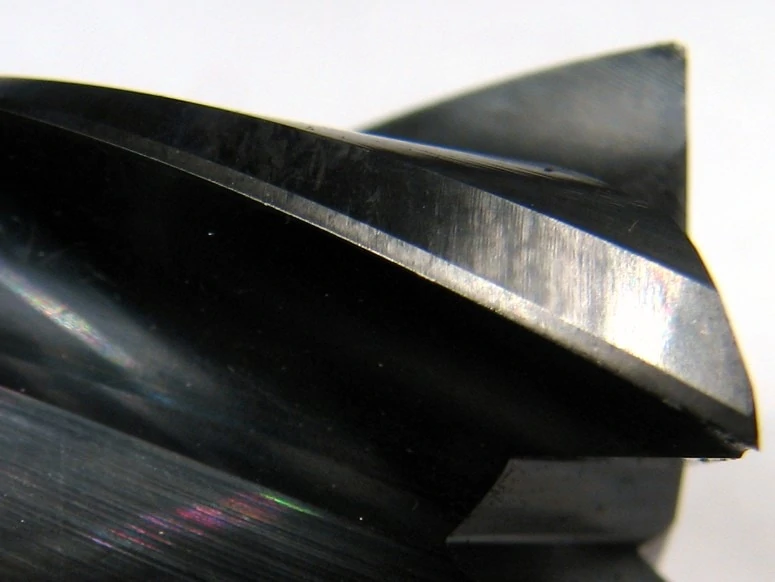

Figure 7 from Evaluation of tool life - tool wear in milling of Inconel 718 superalloy and the investigation of effects of cutting parameters on surface roughness with Taguchi method | Semantic Scholar

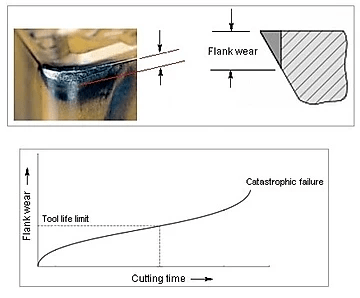

![PDF] Tool Wear Monitoring Tool Wear Monitoring Using Acoustic Emission | Semantic Scholar PDF] Tool Wear Monitoring Tool Wear Monitoring Using Acoustic Emission | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/085896e634c2505bffc5f4c6980981e42838660e/3-Figure2-1.png)